Industrial drones have become essential assets for specialized operations such as geographic mapping, power grid inspections, and emergency rescue missions. These unmanned aerial vehicles require highly stable data links to transmit high resolution imagery and telemetry while receiving real-time control commands. In expansive or infrastructure deficient environments, industrial grade wireless access points and WiFi bridges serve as the primary technology for establishing beyond line of sight communication links. These systems overcome the distance and bandwidth limitations of standard consumer equipment, providing the robust connectivity needed for complex industrial survey tasks.

The performance requirements for industrial drone communication far exceed the capabilities of traditional point to point links. Missions often span tens of kilometers across difficult terrain like mountains and forests, necessitating ultra long range transmission technology. Industrial wireless bridges utilize high gain antennas and advanced interference mitigation to act as reliable data relays, effectively expanding the operational radius of the aircraft.

Advantages and features of the solution

Superior wireless performance

By integrating 4G/5G and MIMO technologies, and using an external antenna, a stable and strong signal is output, building a wide-coverage and highly reliable wireless bridge.

Flexible networking methods

Industrial APs/bridges support flexible networking, enabling the rapid construction of multi-hop, local area, and other networks to fully meet the communication needs of surveying and exploration.

Super strong anti-interference capability

By integrating multi-band switching, MIMO, and smart antenna technologies, an anti-interference core is built to ensure stable and reliable communication in complex electromagnetic environments.

Precise control of multiple devices

Leveraging high bandwidth and QoS, it isolates and transmits various types of data, ensuring stable monitoring and real-time scheduling under multi-device collaboration.

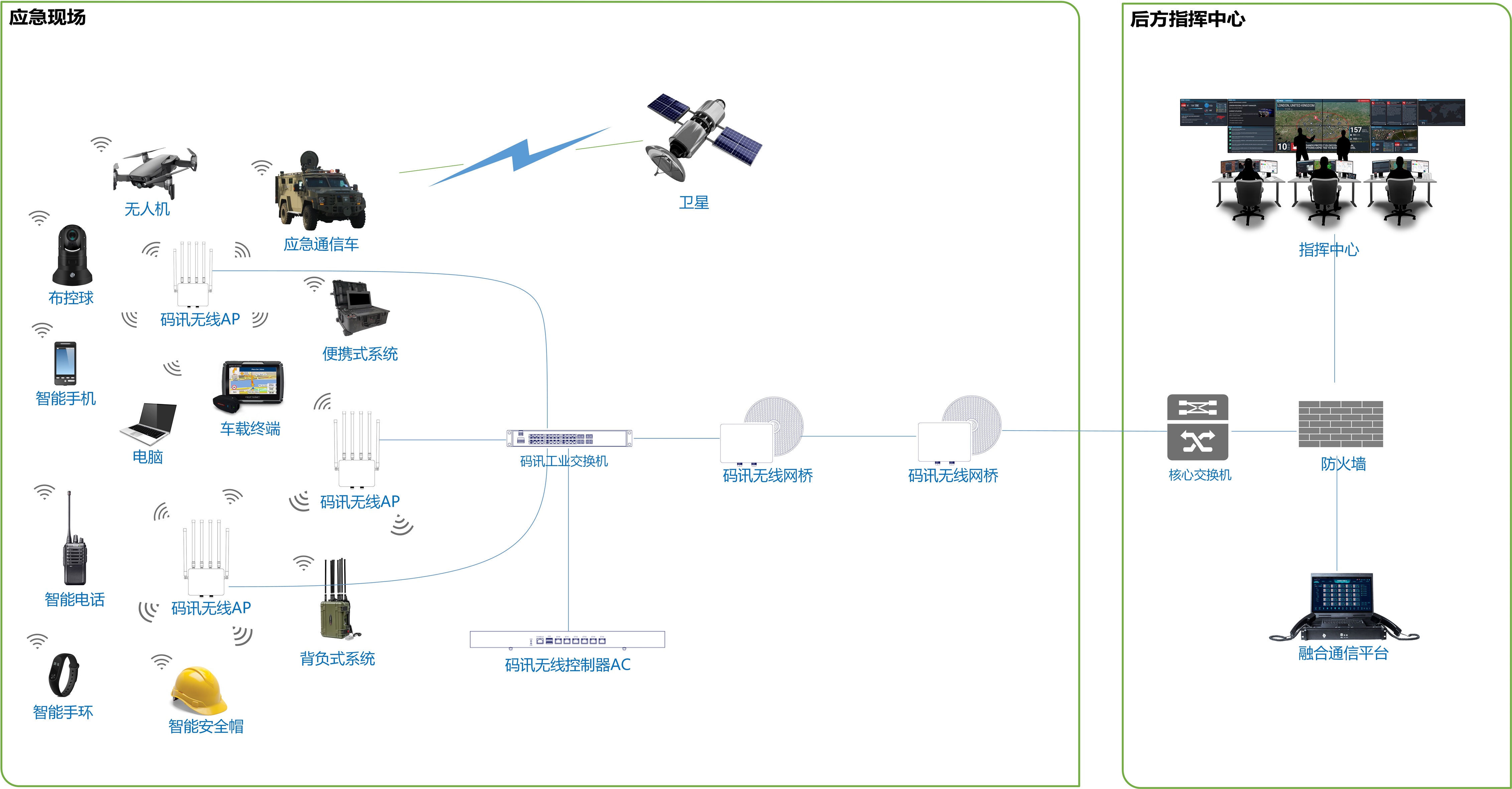

Solution Topology Diagram

Recommended product models and list

|

Feature |

Consumer Grade Gear |

Maxon Industrial Wireless |

|

Transmission Range |

1 to 5 Kilometers |

20 to 50 Kilometers with Relays |

|

Protection Rating |

No IP Rating |

IP68 Waterproof and Dust-proof |

|

Latency Control |

Variable |

Fixed Low Latency for Control |

|

Operating Temp |

0 to 35℃ |

-40 to 75℃ |

Challenges and Necessities are Special Communication Requirements for Drone Surveys.

Drone surveys place extremely stringent demands on communication systems, far exceeding those required of ordinary consumer drones.

First, ultra-long range. Industrial drones operate over wide ranges, often covering tens of kilometers and potentially traversing mountains, forests, or urban areas. Traditional point-to-point communication links are limited. Industrial wireless bridges, with their high-gain antennas and advanced anti-interference technology, enable reliable communication and act as data relays, significantly expanding the drone's operating radius.

Second, high-bandwidth, low-latency, real-time data transmission is essential. Industrial survey drones typically carry high-definition visible light, thermal imaging, requiring real-time data transmission of several megabytes or even tens of megabytes back to ground control centers. At the same time, remote control commands from operators must maintain extremely low latency. Industrial wireless equipment must offer high throughput and excellent quality of service. Environmental adaptability and rapid deployment are paramount. Survey missions often take place in extreme environments such as deserts, high mountains, and the wild. This requires communication equipment with IP68-level protection, wide operating temperature ranges, and the ability to quickly establish and deploy mobile devices.

Durability and rapid deployment are critical factors when conducting surveys in extreme locations such as deserts or high altitude regions. Communication hardware must feature IP68 level protection and a wide operating temperature range to survive these harsh environments. Because survey missions are often mobile, the ability to quickly establish a temporary network is paramount. Industrial wireless equipment is designed for this flexibility, allowing operators to set up mobile command centers and data relay stations in the field without relying on expensive or slow satellite connections.

A three dimensional communication network is often achieved by deploying ground based relay stations along the drone flight path. Industrial WiFi bridges can be positioned at strategic high points to create a multi hop backhaul chain that maintains a constant link between the drone and the ground control station. For instance, during long distance pipeline inspections, a series of relays can be deployed every several kilometers to transmit high definition video of infrastructure health back to a command vehicle in real time. This architecture allows for immediate analysis of potential fault points across hundreds of kilometers of territory.

|

Mission Type |

Communication Requirement |

Recommended Solution |

|

Pipeline Inspection |

Long Distance Transfer |

Multi Hop Wireless Bridge Relay |

|

Emergency Rescue |

Rapid Site Coverage |

Mobile Command Vehicle AP |

|

Power Grid Survey |

High EMI Resistance |

Shielded Industrial WiFi Client |

|

Geographic Mapping |

Massive Data Offload |

High Bandwidth WiFi 6 Bridge |

In emergency response or collaborative field operations, industrial wireless access points provide a unified local area network for multiple drones and operators. These access points utilize quality of service protocols to prioritize flight control commands over video data, ensuring that the drone remains responsive even when the network is under heavy load. By supporting flexible frequency configurations and robust anti interference algorithms, these systems enable command centers to manage several drones simultaneously. This integrated approach is the key driver behind the expanded use of industrial drones for high precision data collection and large scale monitoring.